Production

--- State-of-the-art production

From prototyping to series of fine mechanical parts, we produce everything in highly automated and robotised machine factories (low volume, high complexity, low costs).

More on production

Nijdra has an excellent reputation as a specialist in machining fine mechanical parts. These are often complex and require high accuracy with tight tolerances. In our state-of-the-art machine plants (equipped with climate control, LED lighting and coated floors), we process almost all types of materials. We produce small to medium-sized series. Extensive automation and robotisation allow us to produce precision mechanical turning, milling and grinding parts 24/7.

Our Production capabilities

Turning

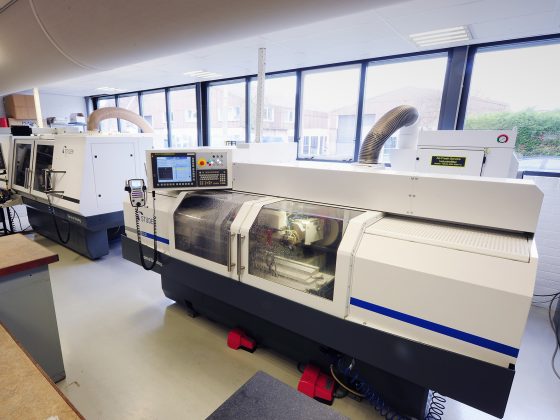

We have several CNC turning machines equipped with automated bar feed and driven tools, among others. In one or two clamping operations, we produce complex parts up to 65 mm in diameter and with tolerances down to 0.005 mm. For larger-diameter parts (up to Ø250 mm), we use sawn material weighing up to 35 kg each. Loading robots also handle feeding into the turning machines here.

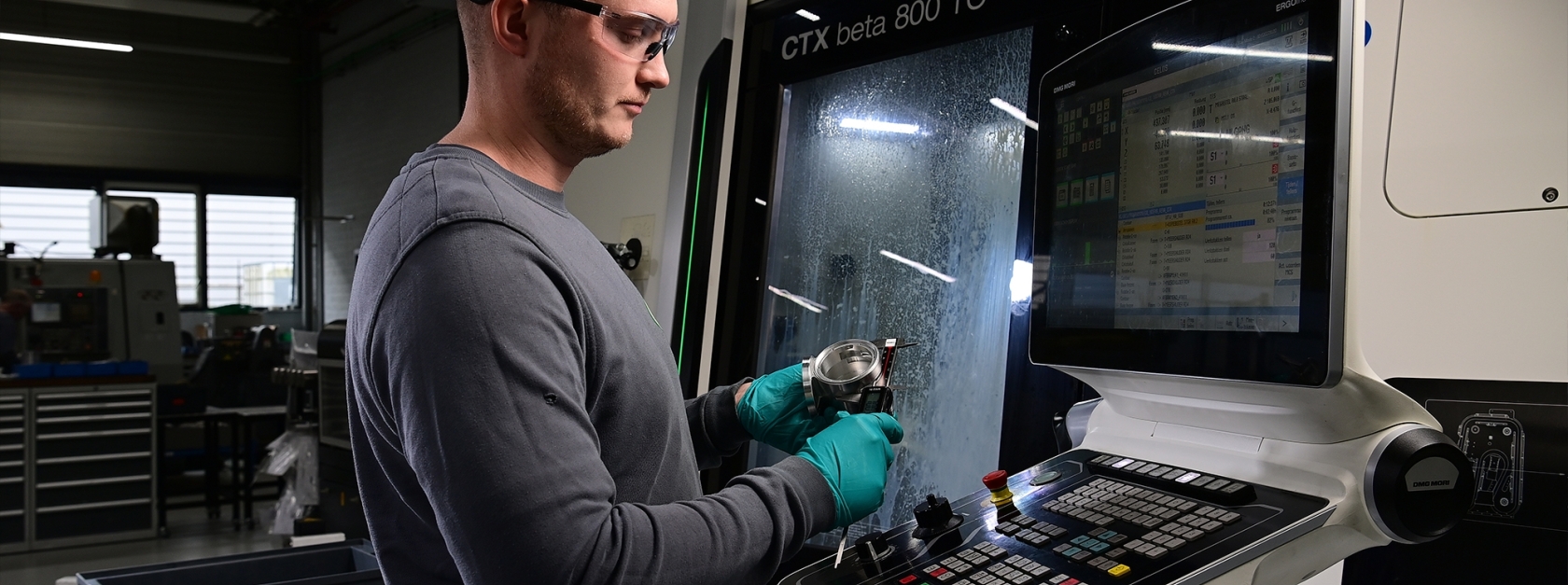

With several 5-axis multitasking machines, we produce complex parts in a single clamping and with fully simultaneous machining. We have two CTX Beta 800 machines with a material passage of Ø 65 mm and Ø 100 mm, respectively. Both machines have 80 different tools. This allows us to be very flexible and keeps setup and changeover times short.

Milling

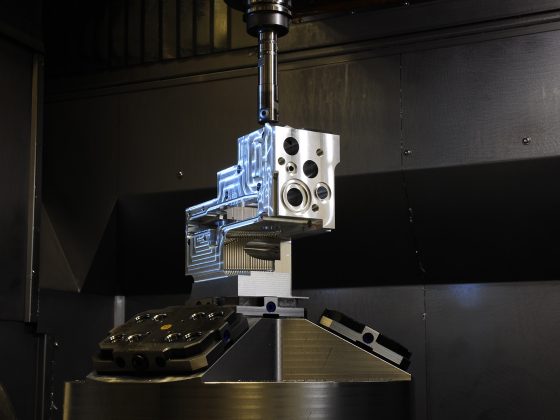

All machining centres in our milling department are 5-axis. They operate fully simultaneously and are equipped with far-reaching automation and robotic handling for both product and pallet handling. This allows us to produce very flexibly day and night. Several machines are even linked together in one cell, allowing us to produce complete milled parts efficiently and unmanned.

The absolute showpiece is our Titanium robotic cell from BMO, coupled with two DMU80Ps from DMG. Both milling machines are equipped with an accurate production package. They are fully thermally stable and capable of full 5-axis simultaneous milling. In doing so, they have a magazine with 270 tools and a machining range of 800 x 1,050 x 850 mm; maximum milling dimensions: 500 x 500 x 500 mm with a tolerance of up to 0.005 mm. The cell is suitable for both product and pallet handling and has space for 39 pallets and 7 drawers.

Grinding

Our CNC-controlled grinding machines are located in an air-conditioned room at 20° Celsius. We grind round and round profile products (up to a diameter of 350 mm) and flat and flat profile products (up to a size of 600 mm x 250 mm) there. We also perform honing, lapping and centreless grinding operations.

Prototyping and small series

For production of prototypes and small series, Nijdra has the Prototyping & Fast Lane Production department. There, the operator watches over the production, production speed and quality of even single pieces of fine mechanical parts.

Quality assurance

Quality and quality assurance are part of Nijdra's DNA (rejection rate of <0.25%). All sites are equipped with a high-quality, air-conditioned measurement room. The production hall is also air-conditioned. As a result, we do not suffer from linear expansion at high and or low outside temperatures. This allows us to produce as well as measure in micron ranges, so that we can meet all customer specifications and requirements.

Nijdra has a certified environmental and quality management system according to ISO 9001 (continuous improvement), ISO 14001 (environment) and ISO 13485 (medical devices).

Thanks to extensive automation and robotisation, we can produce state-of-the-art precision mechanical turning, milling and grinding parts 24/7 for national and international customers from various high-tech industries. For the options, see our extensive machine list via the link.